Activated carbon adsorption desorption catalytic combustion equipment is suitable for treating a wide range of VOCs concentrations. It has good treatment effects on VOCs waste gas with complex composition, low concentration, high flow rate, multiple components, and no recycling value. It has high purification rate, strong adaptability, and no secondary pollution.

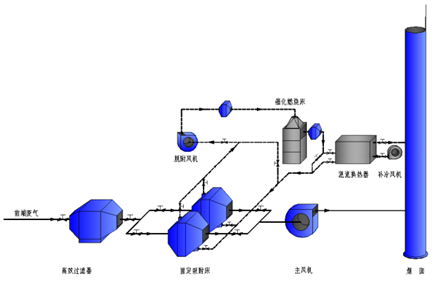

The exhaust gas emitted from workshop production is led out through the air duct and enters the pre-treatment equipment for treatment before entering the activated carbon adsorber. The organic matter in the gas is adsorbed by the activated carbon, and the gas is purified. The purified gas is collected by the collection pipe and then led to the chimney for discharge through the fan.

In this process, there are n adsorbers, and in general, n-1 adsorbers are used for adsorption simultaneously, while the other adsorber is used for desorption. However, the desorption process must be carried out by a single adsorber and cannot be performed simultaneously. When one of them undergoes desorption, the other adsorbers can still perform adsorption operations or stop working, which can achieve continuous operation of the adsorption process.

★ Process flow

★ Equipment advantages

·Suitable for processing organic waste gases at room temperature, high air volume, medium and low concentrations;

·No secondary pollution, low equipment investment and operating costs;

·The adsorbent is made of high-quality honeycomb shaped activated carbon, which has the characteristics of long service life, low operating resistance, and high purification efficiency;

·Catalytic low-temperature decomposition, short preheating time, low energy consumption, long catalyst service life, catalytic decomposition purification rate up to 97%;

·The equipment runs stably and reliably, with few moving parts, a well-equipped maintenance system, and easy operation and maintenance.

★ Scope of application

·This process can be widely used for the purification treatment of low concentration organic waste gases generated in industries such as petroleum, chemical, rubber, paint, coating, furniture, home appliances, printing, etc,

·The types of organic substances that can be processed include benzene, ketones, esters, alcohols, ethers, and alkanes.